Kakusho Metal Vietnam Co.,Ltd

Japanese quality machining.

We specialize in NC automatic lathe machining of brass and provide integrated manufacturing and processing of precision parts.

Company Profile

KAKUSHO METAL VIETNAM

About Kakusho Metal Vietnam

Since our establishment in Vietnam in 2007, we have specialized in metal parts machining with NC automatic lathes. By introducing advanced equipment, we deliver high precision, stable quality, cost efficiency, and short lead times.

We also support prototype production and continuously improve our technology and efficiency. From Vietnam, we remain a trusted metal processing partner for our customers.

Company

Kakusho Metal Vietnam Co.,Ltd

President

CEO: Kenji Chino

Address

Tan Thuan EPZ Road No.22, Tan Thuan E.P.Z., Tan Thuan ward, Ho Chi Minh City, Vietnam

Business

■Metal parts machining using NC automatic lathes

■Assembly processing

Materials Processed: Brass, Other materials available upon consultation

Main Suppliers: Ogitani Taiwan, Mitsubishi Metals (Shanghai)

Machining Size Range: 4Φ~34㎜

Products

– Pneumatic and air-conditioning components

– Plumbing fittings

– Firefighting equipment components

– Gas and connector equipment parts

– Automotive parts

– Stationery components

Established

August 2, 2007

Capital

1,529,000 USD

Contact

TEL: +84-28-37700665–8

FAX: +84-28-37700669

Parent Company

Kakusho Kogyo Co., Ltd.

4589-1 Nakasu, Suwa City, Nagano 392-0015, Japan

URL: http://park2.wakwak.com/~kks-1/

Product Overview

Pneumatic & Air Conditioning Components

We manufacture brass components used for fittings in piping and resin hoses that supply air within factories, such as for air conditioners and compressors.

Threading and hex machining are also supported.

Gas & Connector Equipment Components

We manufacture brass components used for gas nozzles.

Small-diameter drilling and other precision machining are supported.

Automotive Parts

We manufacture brass components embedded in resin parts.

Knurling (anti-slip) and related machining are supported.

Our Strengths

Specialized in Brass Machining

We have long specialized in brass parts machining. By procuring materials in large volumes, we optimize raw material costs and enable stable supply and cost reduction proposals.

Efficient Production with a Lean Team

A small, skilled team operates under a 24-hour shift system for continuous production. This lean structure minimizes labor and equipment costs while maintaining efficiency.

Strict Quality Control System

All products undergo 100% visual inspection. We ensure consistent quality and provide a reliable production system that customers can trust.

Over 60 Years of Expertise in Brass Processing

The Kakusho Group has specialized in brass machining for over 60 years across Japan, China, and Vietnam. Leveraging this accumulated know-how, we deliver high-quality products consistently.

Please feel free to contact us with any questions regarding brass metal machining.

We welcome inquiries starting from prototypes or small-lot production, including consultations based on your drawings.

● Phone Inquiries

028-3770-0665

Weekdays 8:00 ~ 17:00 (Vietnam)

Machining Equipment

CITIZEN: Back-side Machining Equipment

Machining can be performed from both the front and rear sides of the part.

CITIZEN: Equipment for secondary machining

Drilling and other machining on part sides are supported.

Other Machining Equipment

We operate multiple specialized machines to accommodate various part sizes and machining requirements, enabling a stable mass-production system.

CITIZEN: 55 units / TSUGAMI: 6 units

MIYANO: 2 units / Brother: 4 units

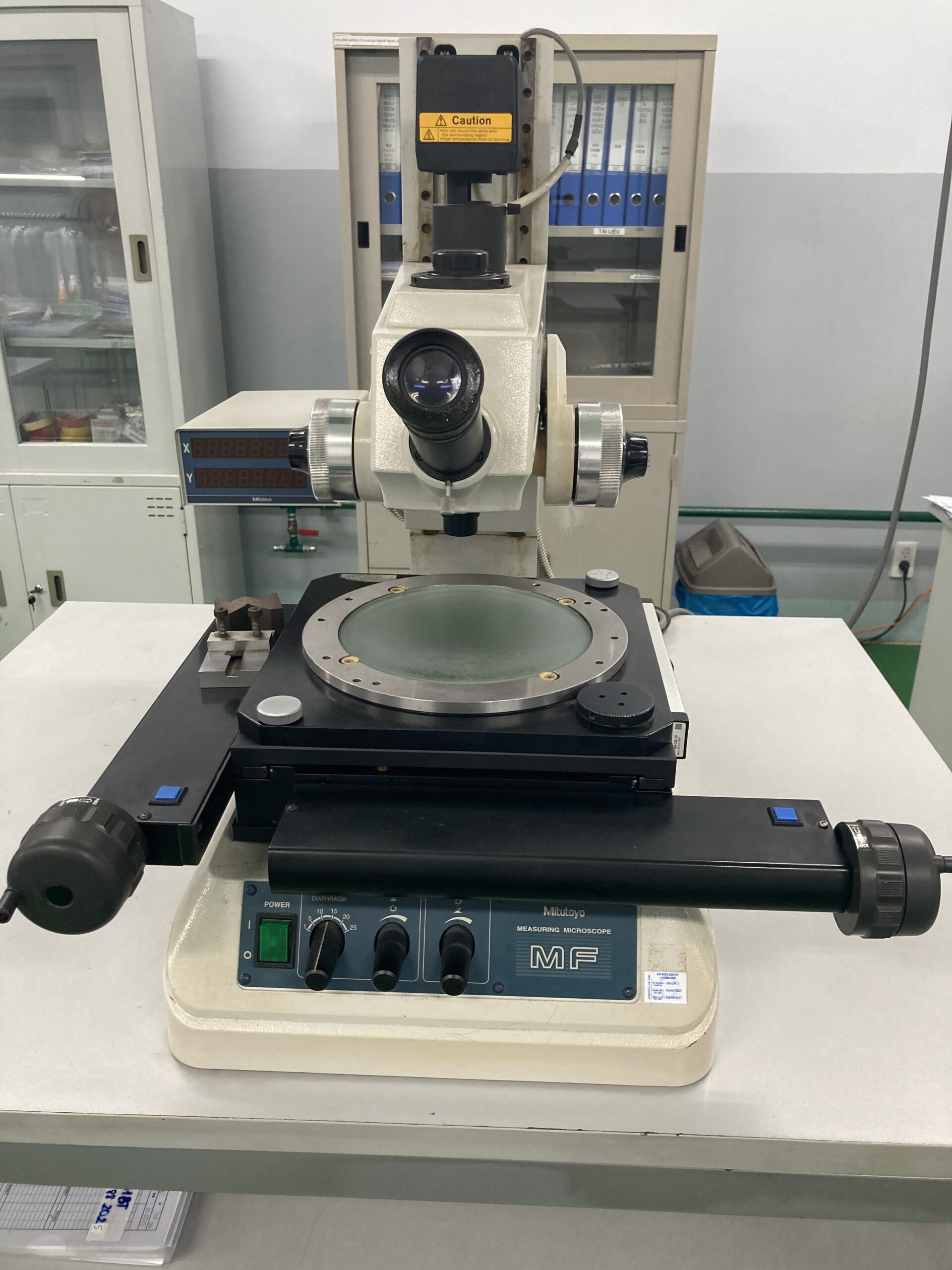

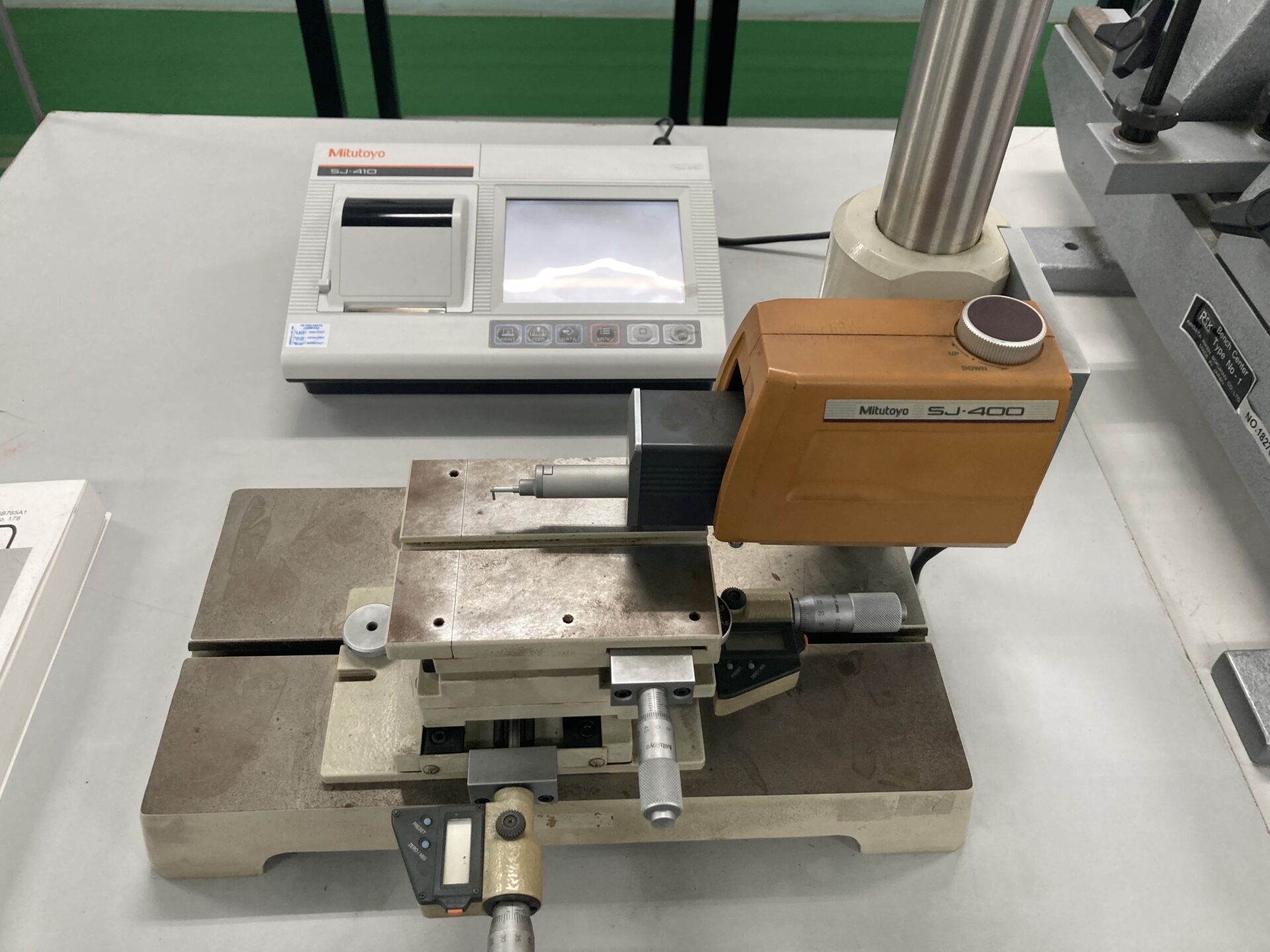

Quality Control

Thorough Visual Inspection

Dimensional Sampling Inspection

Inspections Based on Customer Requirements

Through these quality control systems, we not only prevent visual defects but also detect foreign materials and mixed parts (contamination).

Frequently Asked Questions

If you can’t find the answer here, please feel free to contact us.

Q1. What lot sizes do you support?

Q2. What materials can you process?

Q3. What areas do you deliver to?

Q4. Where do you source your materials from?

Q5. Is a factory visit possible?

Contact Us

Please feel free to contact us regarding available metal processing types and materials.

Please complete the form below and submit.